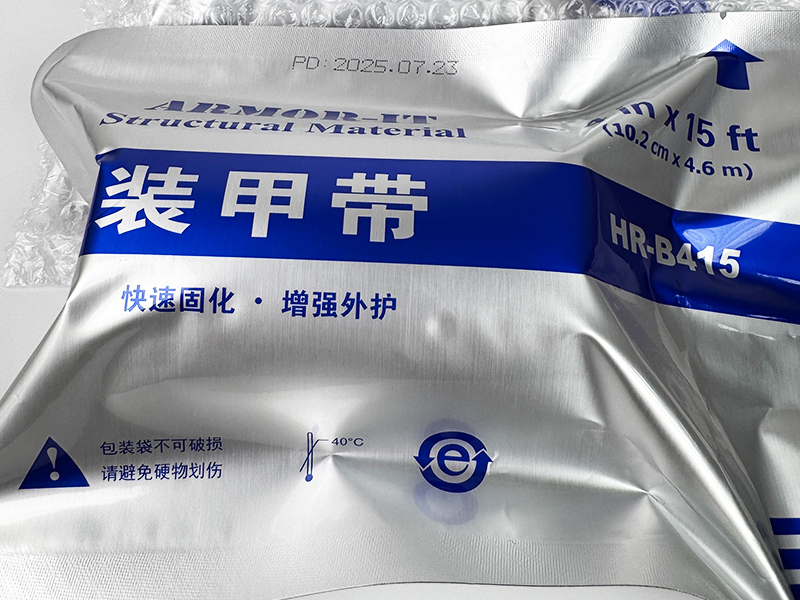

Product Information

Armored tape, also known as fiberglass winding tape, is a type of fiberglass product made by weaving special fiberglass into a high-strength and highly elastic fabric, and then coating the surface of the woven tape with a water cured polymer compound. It has the advantages of easy use, flexible shaping, rapid solidification when in contact with water, and easy operation. The structure formed after solidification has high bending strength and tensile strength, is non-toxic, odorless, and non irritating, and is resistant to water and corrosion. In recent years, it has been increasingly applied in cable accessories for power communication, chemical, marine, mining, automotive manufacturing, medical and other fields.

Usage and application

Armor tape products are sealed in aluminum-plastic composite bags and can be used immediately without the need for special equipment. Simply immerse the tape in water for a few seconds, then wrap and shape it within 3 minutes, cure in 10 minutes, and bear weight after 30 minutes, demonstrating perfect mechanical protection performance.

It is mainly used for connecting the intermediate joints of 10kV, 35kV single core or three core cold shrink cables in the power cable industry, and can also be used for the outer protection of intermediate joints of heat shrink cables. Suitable for reinforcing the outer protective layer of cables and reinforcing the outer protective layer of cable joints and terminals, it is an ideal material for support structure maintenance, protection, corrosion prevention, cable sealing splicing, and high-temperature use in special environmental situations.

Precautions

1. If the ambient temperature is below 0 ℃, in order to achieve curing effect and speed, please preheat the wrapped material and tape to above 2 ℃.

2. In cold and dry winter, the tape can be soaked in water before use, then poured with water and squeezed dry before wrapping.

3. The temperature for soaking the tape in water is around 25 degrees Celsius, not exceeding 50 degrees Celsius. If the water temperature is too high and soaked for a long time, it will solidify quickly and harden before it can be operated.

4. In warm and humid areas during summer, adhesive tape does not need to be soaked in water. After wrapping, water can be sprayed onto the surface to accelerate curing speed and increase adhesion strength.

storage

It should be stored indoors at around 20 ℃ in a well ventilated, dry, and clean environment.

Validity period

Three years from the date of production.